The entire surface of the workpiece can be tooled and finished by clamping with a maximum of torque transmission.

NEIDLEIN face drivers of type FSP/FSPB/SP with drive disks are mechanical clamping systems which are suited for soft / green as well as heavy tooling. In application, they feature maximum flexibility and high robustness.

These face drivers are power-operated by the thrust of the tailstock. Workpieces are clamped centrically using a movable center pin. This way different centerings can be adjusted, thus ensuring a constant datum-point at the face end of the workpiece.

NEIDLEIN face drivers FSP/FSPB/SP ensure:

- a maximum of torque transmission, thus achieving high metal removing rates

- datum-point at the face end of the workpiece, stable datum-point in case of different centerings

- compensating drive disk for uneven face sides

- high flexibility in the application, wide range of clamping diameters

- fixed center pin in clamped condition » fixed clamping point

- run-out deviation in the process: 0.015 - 0.02 mm

- adjustable spring force (depending on the weight of the workpiece)

- low setup costs due to fast change of drive disks and center pins

- cost efficient exchange of parts that are in contact with the workpiece (changeable carbide inserts)

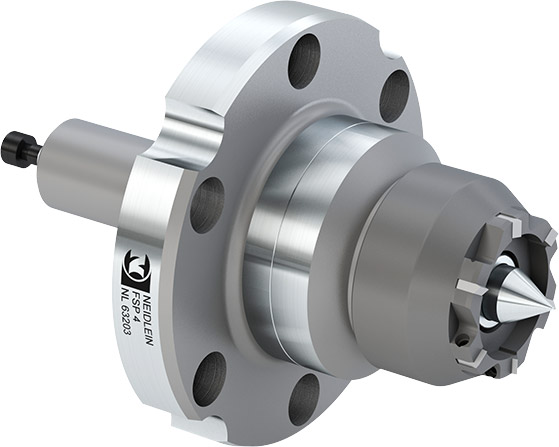

Type FSP

with flange retainer for screw connectionType FSP is mounted onto the machine spindle nose using a flange adapter.

Type FSPB

with flange retainer for jaw clampingType FSBP is directly clamped with the chuck using soft jaws.

Type SP

with taper shankType SP with taper shank for direct mounting into the machine spindle.